品中心英文-14310093931.jpg)

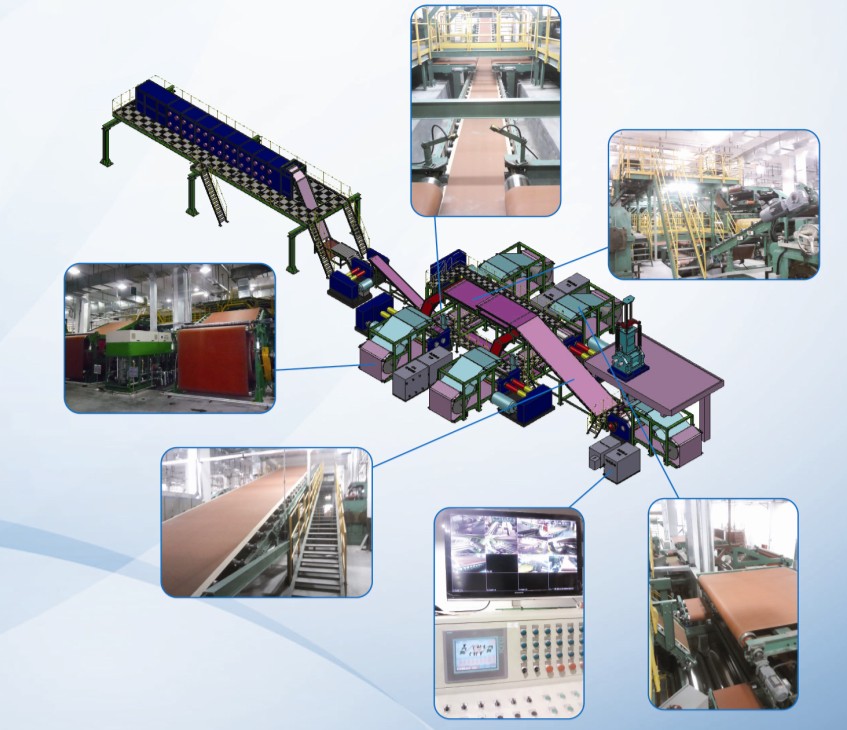

Rubber is pre-mixed in a internal mixer. Andthen it is further mixed and compounded in open mills. After the automatic andcontinuous process, the final product is given. This is the one-stop rubbermixing system.

This system improves the quality andproductivity of rubber mixing. The long time of mixing in mills raises thedispersity of additives and chemicals, which improves stability and homogeneityof rubber materials. Furthermore, the abrasive resistance and rollingperformance of tires are improved.

Overview:

Rubber is pre-mixed in a internal mixer. Andthen it is further mixed and compounded in open mills. After the automatic andcontinuous process, the final product is given. This is the one-stop rubbermixing system.

This system improves the quality andproductivity of rubber mixing. The long time of mixing in mills raises thedispersity of additives and chemicals, which improves stability and homogeneityof rubber materials. Furthermore, the abrasive resistance and rollingperformance of tires are improved.

Components:

Up-stream equipment

Internal mixer

Receiving hopper

1st open mill (cooling)

Sulfur based master batch

Shunt conveyor lines

2nd open mill

Combine conveyor lines

Sheeting mills

Batch off units

Auto control system

Steel frame, security protection,monitoring module, etc.

Technical parameters:

煉膠生產(chǎn)線-英-d33e1298-bf64-4875-b150-ed98aae917a6.jpg)

京ICP備05048247號 版權(quán)所有 北京萬向新元科技有限公司 E-mail